Dust removal of absorbing nonwovens

Xstream high speed non contact surface cleaning technology ensures a dust-free process to ensure a high quality product.

New Hildebrand Customer Laboratory in Gossau

Are dust contamination and static charge issues problems in your daily production process? We offer comprehensive testing for a wide range of materials.

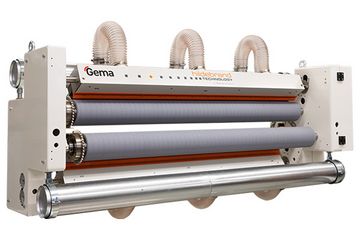

Winterhalder - Highest product quality thanks to high deionization

The iONstream 4.0 bar delivers high deionization performance without the use of compressed air, is easy to install and delivers a high reliability.

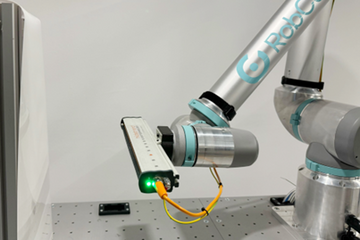

Maximum flexibility thanks to robot-guided discharge bar iONstream 4.0

The iONstream 4.0 discharge bar, which is mounted directly on the robot arm, offers high discharge performance without the use of compressed air.

iONstream 4.0-VC bar with vertical connector

Electrostatic discharge of a large web width with several iONstream 4.0-VC mounted in a line.

Discharging of big injection molded parts with iONstream 4.0

With our robust and efficient iONstream 4.0 discharge bars and their easy positioning even big injection molded parts can be discharged after the cooling process, without using air.

Discharging of small injection molded parts with iONstream 4.0

Our durable and efficient iONstream 4.0 discharge bars effectively neutralize these charges without the use of air, easily discharging even the smallest parts after cooling.

uvex - Best quality injection molding with iONstream 4.0

The iONstream 4.0 discharge bar is mounted twice on the robot arm. It provides a high level of electrostatic discharge without the use of compressed air.

Charging technology for temporary attachment

With the 20kV iONcharge 4.0 electrostatic charging system textile and carpet materials can be easily charged for temporary attachment, before fastening.

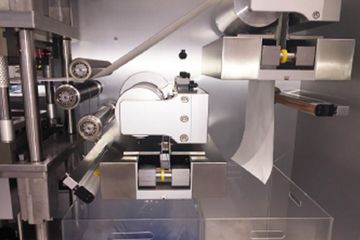

Pharmaceutical film converting with Xstream web cleaner

Non-contact particle removal from high-quality sterile medical packaging film with the Xstream web cleaner.

Dunmore - Intelligent electrostatic discharging

High discharge performance through the use of iONstream 4.0

Xstream complete module

Xstream for surface cleaning applications, including side frames, side doors, special brackets which enable swiveling of the Xstream modules between "in" and "out" of cleaning position.

Easy installation

Quick and easy! Our iONstream 4.0 discharching bars can be integrated into the existing customer system with iONclip or iONmount.

Static control

iONstream 4.0 prevents static charge during the film folding process and improves quality.

Swiss Quality

From project planning and customisedtechnical solutions to complete commissioning - we support you with our experienced staff.

System advantages Xstream

The Xstream brings forth an innovative solution that enhances quality, minimizes downtime, and maximizes profitability.

Static removal sheeter application

iONstream 4.0 network-capable AUTO DC Technology® static neutralising system.

Charging technology for surface protection

The 20kV iONcharge 4.0 high voltage generator, the ultimate solution for effortless charging of various materials, including paper, for temporary fixation on metal surfaces.

Long distance static removal unwinding process

The iONstream 4.0 uses advanced electrostatic neutralisation techniques and ensures a consistent neutralisation process. This means you can maintain optimal performance and productivity regardless of the specific conditions.

Bleher Folientechnik GmbH - High discharge performance through the use of iONstream 4.0

Our iONstream 4.0 offer high discharge performance, ensuring that you get the most out of your upgraded system. With improved efficiency and optimized performance, you can expect better results and enhanced productivity.

Efficiency control of ionisation and web cleaning system

iONgate bus interface connected to several iONstream 4.0 ionisation bars and Xstream web cleaning modules.

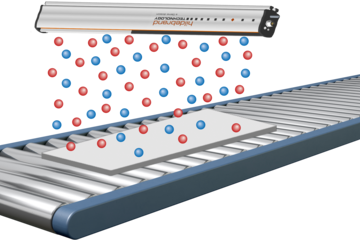

Advantage iONstream 4.0 vs. Disadvantage Air ionizer

Non-contact removal of all particles on any high quality film during its manufacturing process WITHOUT AIR IONISER!

Retrofitting in the crosslapper

Ionisationsystems in the crosslapper at BWF Envirotec. The BWF Group. Regionally rooted, globally leading.

Analysis of current electrostatic situation

Monitoring and permanent recording of electrostatic charge in production using iONsense and iONcontrol.

Surface cleaning of flame resistent textiles

Non-contact removal of all loose fibers and particles during the slitting process of fire resistant textile.

Extension of the test facility

Extension of the test facility with 2 pneumatic Dienes knife holders and the Hildebrand Technology SLITstream system – the perfect combination!

Retrofit for quality assurance

Monitoring and permanent recording of the specified residual charge on the workpiece, through iONsense, iONcontrol with iONstream 4.0.

Retrofit of ionisation system

iONstream4.0, 6kV, 12kV and 18kV, for short, medium and long ranges, AUTO DC Technology® - ionising bars.

Static removal unwinding process

iONstream 4.0 network-capable AUTO DC Technology® static neutralising system.

Static removal gravure printing process

iONstream 4.0 network-capable AUTO DC Technology® static neutralising system.

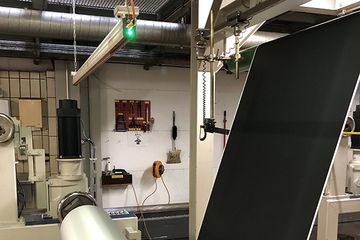

Static control for solar panel film coating process

iONstream 4.0 network-capable AUTO DC Technology® static neutralising system.

Efficiency control of ionisation system

iONcontrol industrial panel connected to several network-capable AUTO DC Technology® ionising bars iONstream 4.0.

Slitting dust removal

The SLITstream cutting dust removal for slitting units was especially developed to remove the generated dust directly at the knives.

Technologies from Dienes and Hildebrand Technology complement each other perfectly in the production process.

Dust removal system Xstream battery separator film

Xstream high velocity non-contact surface cleaning with AUTO DC Technology® ionizing system for PP/PE and PTFE film of 2-400µm.

Static control for film powder coating

iONstream 4.0 network-capable AUTO DC Technology® static neutralising system.

Static control for automatic reel change over process

iONstream 4.0 network-capable AUTO DC Technology® static neutralising with charging function system.

Compact dust removal printing process

Xstream high velocity non-contact surface cleaning with AUTO DC Technology® ionising system

Dust removal tissue process

Xstream high-speed surface cleaning technology with AUTO DC Technology® system.

Electrostatic discharge spray coating process

iONstream 4.0 network-capable AUTO DC Technology® static neutralising system.

Electrostatic discharge

iONstream 4.0 the 100% solution for turret winders!

Dust removal before corona treatment

Cleaning the substrate before the corona treatment stations can be crucial and saves costs!

Electrostatic charge in the lamination process

iONcharge 4.0 - perfect electrostatic charging without charge losses via high voltage cables.

Electrostatic discharge during high-speed paper production

Improve your static control with the iONstream 4.0 network compatible AUTO DC Technology®-ionization system.

Dust removal in textile production

Xstream high-speed surface cleaning technology with the AUTO DC Technology®-system.

Electrostatic discharge Bopp/Bopet

iONstream 4.0 network compatible AUTO DC Technology®-system for neutralizing static electricity.

Electrostatic discharge in the coating process

iONstream 4.0 network-capable AUTO DC Technology®-system for neutralizing static electricity.

Dust removal BIAX-FILM up to 12 m web width

Xstream XL-Modular high-speed contactless surface cleaning technology with the AUTO DC Technology®-ionization system.

Dust removal in paper production

Prevent dust and loose fibers in paper products with Xstream high-speed surface cleaning technology.

Dust removal in the blown film process

Avoid dust and loose fibers on the film surface before rewinding with Xstream highspeed surface cleaning technology.

Surface dust removal in the winding process

Benefit from contactless cleaning efficiency with the Xstream system when producing pharmaceutical film for packaging.

Electrostatic charging of nonwoven and fabric material

With the 20kV iONcharge 4.0 high voltage generator, nonwoven and woven materials can be easily charged to significantly improve filtration properties.

Surface dust removal in the coating process

Improve your dust control with Xstream highspeed contactless surface cleaning technology with the AUTO DC Technology®-ionization system.

Surface dedusting in glass production

Benefit from Xstream technology for highspeed, contactless surface cleaning for your glass production.

Electrostatic discharge in the winding process

Improve your static control with the iONstream 4.0 network compatible AUTO DC Technology®-ionization system.

Surface dust removal in nonwoven processing

Improve your dust control with Xstream high-speed contactless surface cleaning technology with the AUTO DC Technology®-ionization system.

Kiseung Inc. - XStream for silicone separating foil and paper

Kiseung Inc. has been supplying "customized silicone release products" since its establishment in 1999 to meet the demand in various household industrial fields, ranging from pharmaceuticals, automobiles and LCD to electrical/electronic fields such as cell phones.

Xstream system for foil coating

A reliable cleaning system is essential for preliminary dust removal prior to film coating. Hildebrand Technology offers the Xstream surface dedusting system for this purpose.

Xstream system for the pharmaceutical industry

A manufacturer in the pharmaceutical industry uses two Xstream standard modules for its plant, as well as two iONstream unloading systems.

Xstream System for plastic

For a manufacturer of packaging materials, Hildebrand Technology has deployed two Xstream surface dedusting systems, as well as the iONstream electrostatic discharge system.

Xstream and SLITstream system for nonwovens

Hildebrand Technology has successfully installed two Xstream surface dust collection systems and 40 SLITstream cut dust collection systems for a worldwide known manufacturer of slitting machines and winders in the nonwovens industry.

Grenzebach - Xstream system for display glasses

Grenzebach is a leading global company specializing in the automation of industrial production lines.

Stuermsfs - Ionization system for metal processing machine

The use of the iONstream 4.0 electrostatic discharge system makes it possible to discharge <=500 V, allowing system operators to work safely.

Bachmann Forming - Ionization system for thermoforming plant

With the installation of the electrostatic discharge system iONstream 4.0, a discharge of <= 200V is possible. This allows a fast and uniform production process.

Rohrer AG - Ionization system for pharmaceutical packaging line

Hildebrand's iONstream 4.0 ionization system puts an end to cutter blockages and machine downtime. The system automatically adapts the correct discharge polarity and neutralizes the charged substrate.

GGM Manufacturing - Ionization for plastic booth systems

GGM Romania produces plastic cabin parts for electrostatic powder coating. Hildebrand installed the iONstream 4.0 ionization system to optimally neutralize the charged plastic panels before further production steps.

Gravure Printing - iONstream 4.0 in EX Zone 1

Gravure Printing is a leading company in the field of packaging gravure printing in Korea. Hildebrand has successfully installed the iONstream 4.0 ionization system in EX Zone 1 on 11 lines.

Jindal BOPP slitter rewinder - most modern antistatic systems

Jindal is the largest manufacturer of BOPET and BOPP in India. Thanks to the iONstream 4.0 ionization system, Jindal is able to neutralize the charged substrates as efficiently as possible.

Advanced antistatic and web cleaning systems

Perfect neutralization results and efficient dust removal with the ATEX certified iONstream 4.0 ionization system.