System Description

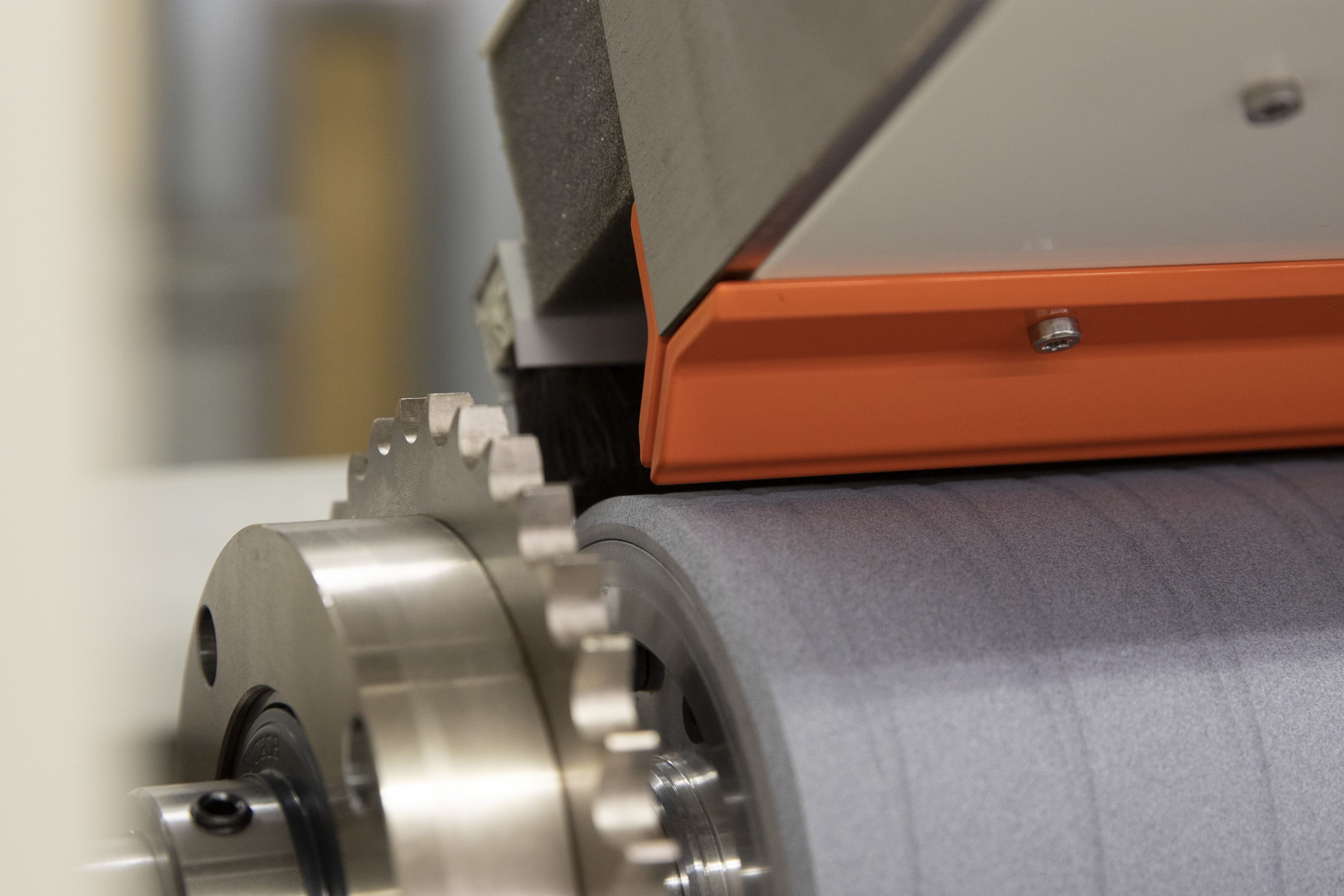

The Xstream non-contact web cleaning system adopts a revolutionary approach to improve quality, reduce down time and boost profitability. It combines the latest aerodynamic nozzle technology with a defined high speed vacuum airflow and substrate ionization prior to cleaning within one turnkey system. It is positioned above an idler roller as close as possible prior to the problem zone.

Electrostatic discharge

In many cases electrostatic charge present on the substrate surface is a major factor in increasing contamination and makes particle removal more difficult. This is why our static control system is always installed prior to the cleaning process to guarantee a neutralised substrate surface and therefore facilitate easier removal of all particles.

For more information follow the this link: Know-how - Dust Removal

Technology

The special aerodynamic nozzle of the Xstream and Xstream ULTRA which is positioned close to the surface of the substrate generates, through the ombination of vacuum in the cleaning module and web speed, an extremely high velocity airflow (>60 m/s). The high velocity air flows along the substrate surface to the nozzle edge and into the cleaning module. The high velocity airflow breaks the boundary layer on the substrate and forces he particles that were trapped in this layer into the cleaning module. From the cleaning module the particles are transported to a filter unit.