System Description

iONstream 4.0 is a high performance AUTO DC Technology® static neutralising system. It incorporates the latest technological developments and is micro-controller operated with local embedded intelligence. Electrode contamina-tion and emitter pin status, as well as neutralising efficiency, are continuously monitored and visualized. Each neutralising bar is accessible via a GateWay or via the iONcontrol touch panel. Parameters can easily be read and controlled by process engineers. The specially developed AUTO DC Technology® senses the polarity of the charge on the target substrates surface and automatically corrects the pulse/pause relationship towards the dominant polarity surface charge in order to achieve maximum neutralising effect. All electronic components and high voltage parts are encapsulated inside the bar profile. The System is available in three versions (6, 12, 18 kV) for normal, long and very long neutralising range and very high web speed.

Application:

- AUTO DC Technology®

- 24V DC supply, all electronic components integrated in neutralising bar profile

- Extremely high remote real power

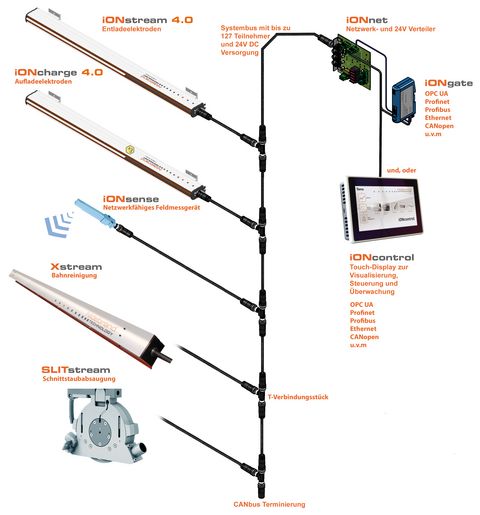

- Network compatible through CANbus

- Plug & Play

- Data visualisation via App

- Data transfer via WLAN, OPC and any field bus

- Ex Electrode and field strength meter integrated in the same network

Technology

By applying alternate positive and negative high voltage current to the emitter pins, ions of both polarities are generated. iONstream 4.0`s special AUTO DC Technology® generates substantially more ions due to its perfect control of the pulse/pause relationship and therefore provides a much more homogenous electrostatic field when compared to any other conventional PULSEDC method neutralising systems. The highly efficient pin shape and its sharpness is maintained during the full life time of the neutralizing bar. Our revolutionary design of the static neutralizing bar is constructed with a special glass fibre re-enforced extrusion incorporating non-metallic shields which work in harmony with the electrostatic field of the emitter pins. The result of this revolutionary technology and intelligence is an effective neutralising range of up to 1'500mm in certain applications. The expert DOE software, in combination with its real time micro-controller functionality, allows easy integration into todays industrial fieldbus as well as Ethernet networks.