Are you experiencing dust contamination problems on your substrates? Does static charge on your material bother you?

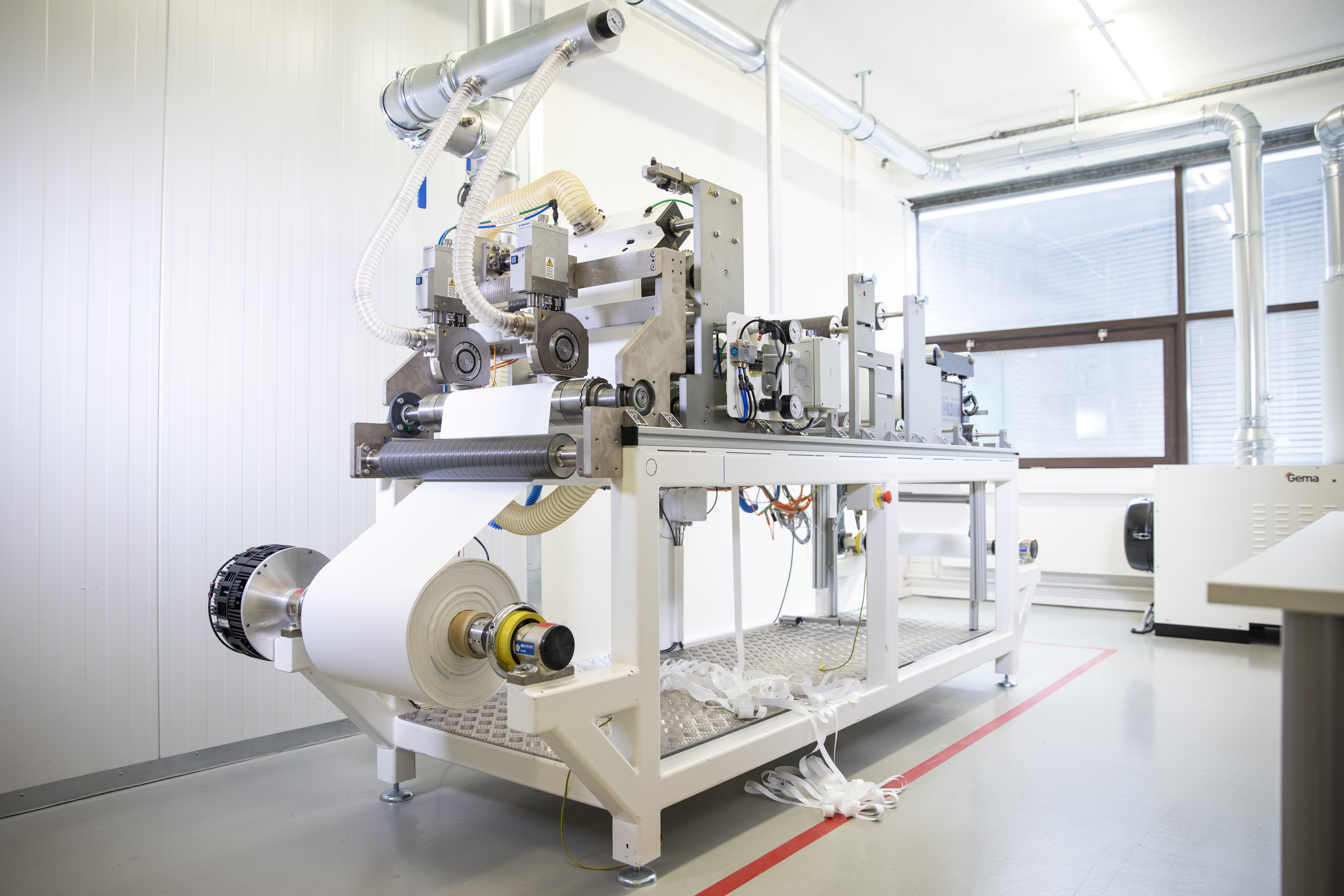

We are ready for your challenge! At our headquarters in Gossau (Switzerland) we offer you the opportunity to test your materials such as film, foil, textile, paper etc.

Contact us for your individual trial.

Further information and technical specifications for our laboratory in Switzerland can be found in our flyer.

Click here to download.

iONstream 4.0

iONstream 4.0 is a high performance AUTO DC Technology® static neutralising system. It incorporates the latest technological developments and is micro-controller operated with local embedded intelligence. Electrode contamina-tion and emitter pin status, as well as neutralising efficiency, are continuously moni-tored and visualized.

Xstream

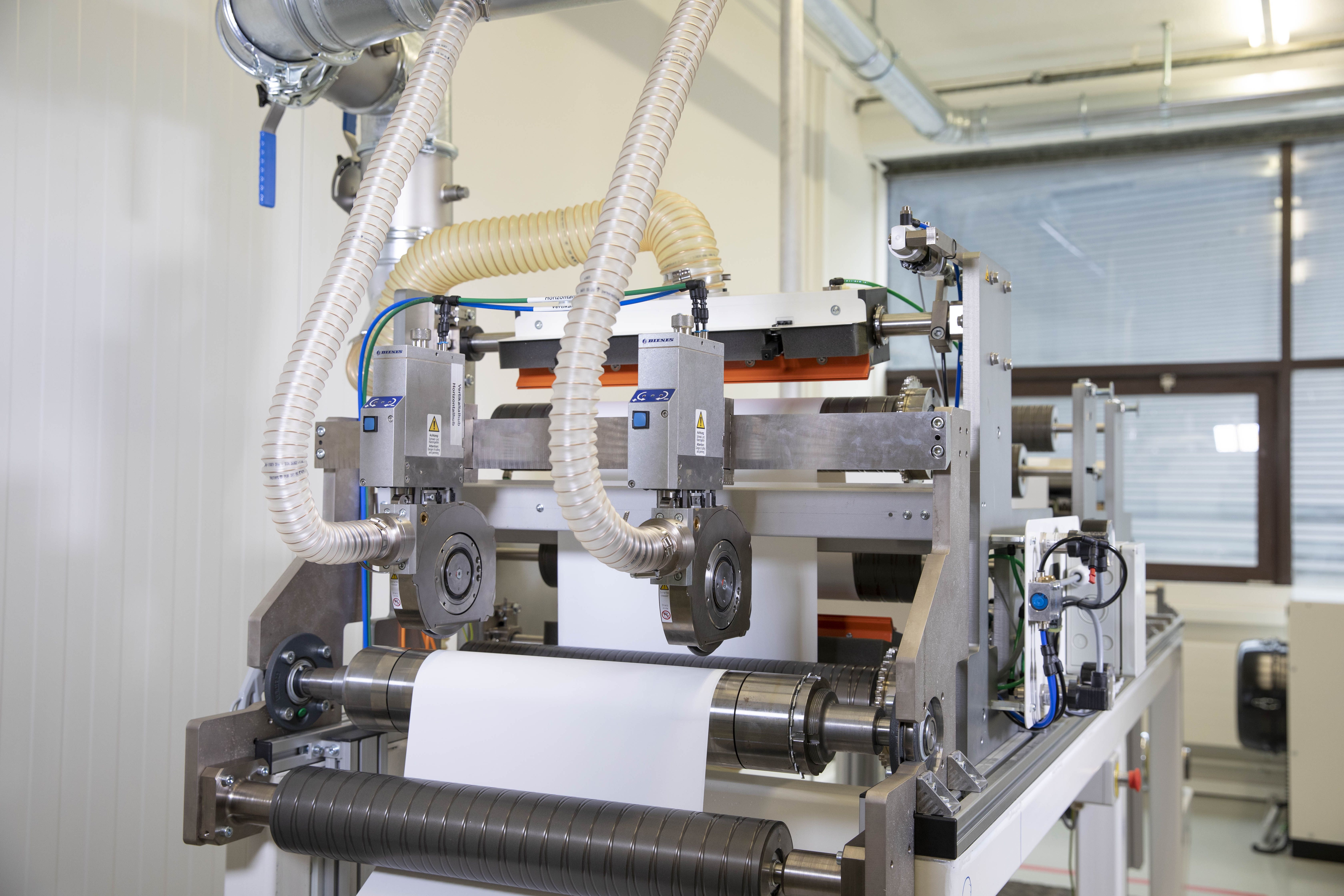

The Xstream non-contact web cleaning system adopts a revolutionary approach to improve quality, reduce down time and boost profitability. It combines the latest aerodynamic nozzle technology with a defined high speed vacuum airflow and substrate ionization prior to cleaning within one turnkey system.

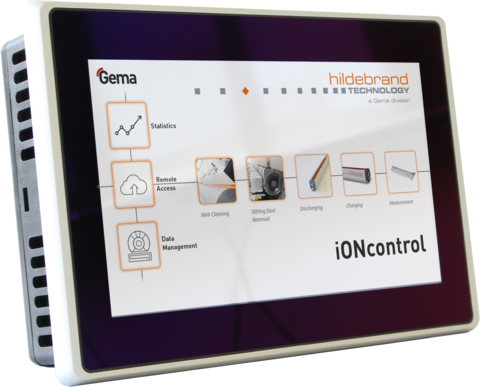

iONcontrol

The control system has been redesigned by Hildebrand Technology and optimized for industry 4.0 applications. The entire system can be controlled via the industrial touch screen iONcontrol with its self-explanatory user interface. Explicit icons, clear statistics and logical menu navigation make operation on the industrial panel easy for every user.

SLITstream

The SLITstream cutting dust removal for slitting units was especially developed to remove the generated dust directly at the knives. The new dust removal extraction hood generates a high air flow within the system directly at the upper knives. This extreme sharp air jet removal also the smallest particles.